Scroll to:

Turning Water Pollution Sources Into Assets: Exploring Innovative Options Of Using Abandoned Mines For Generating And Storing Renewable Energy

https://doi.org/10.24057/2071-9388-2020-03

Abstract

For citations:

Winde F. Turning Water Pollution Sources Into Assets: Exploring Innovative Options Of Using Abandoned Mines For Generating And Storing Renewable Energy. GEOGRAPHY, ENVIRONMENT, SUSTAINABILITY. 2020;13(2):6-16. https://doi.org/10.24057/2071-9388-2020-03

INTRODUCTION

Extracting large amounts of rock from the geological underground at ever increasing depths invariably leads to rising volumes of water ingressing into the created void system. In order to prevent underground workings from gradual flooding this water needs to be continuously removed through pumping. Where pumping rates exceed the natural groundwater recharge for prolonged periods of time this eventually leads to the lowering of groundwater tables and the associated dewatering of overlying aquifers. Through the collapse of near-surface mine tunnels, desiccation of previously saturated soil strata and accelerated subterranean erosion this, in turn, often results in geotechnical ground instability causing subsidences, sinkholes etc.

Worldwide, mine water management is generally among the longest-lasting and costliest parts of post-closure remediation (e.g. Paul et al. 2015; Eberfalvi et al. 2015). In order to reduce associated financial burdens global efforts are underway to find innovative ways of making post-closure water management more affordable and economically as well as ecologically sustainable. This need is especially pressing for developing countries where the bulk of global mining currently takes place, and which have the least resources to mitigate associated impacts that often are more severe than in developed nations. The problem is likely to intensify in future as consumption of mineral resources continuous to grow driven by population growth and improved lifestyles. While mining of conventional fuel such as coal, oil, gas and uranium may decrease in future this is counterbalanced by extracting growing amounts of partly very rare minerals used, for example, in wind turbines (e.g. neodymium and dysprosium for magnets), solar panels (e.g. indium, cadmium, tellurium), electrical cars (lithium) and electronics. For 2050, predicted requirements for praseodymium, dysprosium, terbium, neodymium and indium range between 4 and 12 times the total annual production in 2017, respectively (Ahmed 2018). Owing to their relatively low natural abundance this will result in ever larger ore volumes to be mined increasingly impacting on the environment. Generally, renewable energy requires more mineral resources per energy unit generated than conventional energy forms (Ghenai and Janajreh 2013; Acatech 2017). As most future mining is set to continue taking place mainly in developing countries where social acceptance is higher than in affluent societies, proactive efforts are needed at an international scale to prevent exacerbating global disparities further fuelling political instability, regional conflict and mass migration.

Against this background the present paper illustrates impacts and costs associated with the post-closure flooding of underground mines using international case studies before exploring a range of existing technologies on generating and storing renewable energy to tackle mine water legacy issues in a sustainable manner. The main objective is not to assess the viability of the various technological options but rather to propose their innovative applications in the context of closed mines.

POST-CLOSURE LEGACY COSTS: CASE STUDIES FROM SOUTH AFRICA AND GERMANY

(i) South African gold mines: In dolomitic goldfields of South Africa, where deep-level gold mines dewatered large karst aquifers this led to the drying up of natural karst springs and boreholes previously used for agricultural irrigation as well as to the destruction of infrastructure including roads, railways, residential houses and industrial plants, often with catastrophic consequences and loss of life (Winde and Stoch 2010). Apart from associated economic damage this also changed the hydrological characteristics of the affected landscape, inter alia, through increasing groundwater recharge rates via hundreds to thousands of newly formed sinkholes directly channelling surface runoff underground. Consequently, pumping rates at deep-level mines increased well-above natural levels as indicated, for example, by pre-mining spring flow volumes. Combined with the ever-increasing depth of mining reaching levels of up to 4000 m below surface the rise in pumping volumes placed a significant financial burden onto affected mines some of which have to pump 70 to over 100 Ml per day. If these mines close and are subsequently flooded water flowing into adjacent voids adds to the pumping load and potentially shortens the lifespan of receiving mines. Following the unplanned and haphazard closure of mines in the Western and Central Basins (near Johannesburg, South Africa) subsequent flooding resulted in the uncontrolled decant of highly polluted acidic mine drainage (AMD) contaminating ground- and surface water resources. In order to protect water resources as well as shallow underground infrastructure such as the basements of high-rise buildings, government installed underground pumps to keep mine water from exceeding critical levels. The extracted water is neutralised through liming before being discharged into nearby streams still containing all salts and most contaminants such as uranium. After the storage capacity of adjacent mine tailings was exhausted the toxic sludge generated by liming at the high- density sludge plant is now pumped back to the underground void from which the mine water is extracted essentially creating a closed loop that increases pumping rates as well as pollution levels. For treating a total volume of some 130 Ml/d of AMD in the mid-term (approximately 5 years) government allocated R 15 bn (just under € 1bn) (Winde and Stoch 2010). With all three flooded mining basins underlying densely populated urban areas the pump-and treat approach needs to be maintained in perpetuity. According to long-term plans the pumped mine water will in future be treated to potable standards via reverse osmosis recovering associated costs through a levy on drinking water. This would effectively burden associated costs onto the general public rather than former mine owners violating the polluter-pays principle.

With more than 300 Ml of mine water per day currently still being pumped by active gold mines future treatment costs are set to almost triple once those mines close. This would render the current pump-and-treat approach unaffordable in the long run especially considering the sluggish economic development and persisting spending priorities such as housing, health, education, social welfare etc.

(ii) German hard coal mines: While affordability may be different in Germany, mining-related water problems are similar as, for example, the 'Ruhrgebiet' shows. After more than 200 years, hard coal mining in the Ruhr area, once the economic powerhouse of Germany, finally ceased in December 2018. Mining-induced ground subsidence has left large tracks of land sunken below the natural water level of local rivers such as Rhine, Ruhr, Lippe and Emscher with surface water ponding in drainage-less areas. In some instances, even the direction of stream flow was reversed. This necessitated hydrological engineering employing polders (artificially impounded water bodies) and pumping at surface in order to restore drainage. To avoid that sunken densely populated areas are submerged by rising mine water once mines close, perpetual pumping is required. Pumping volumes in 2016 were around 180 Ml/d (66 Mm3/a) and are predicted to eventually level out at an average of about 300 Ml/d (110 Mmfi/a). Together with polder maintenance and limited groundwater treatment (mostly at former cookeries) post-closure water management is estimated to require € 220 million per year from 2019 onward (Dombrowski 2018, RAG 2019).

In contrast to South Africa these costs are not covered by government or levies but by proceeds (interest) from a € 14.3bn- investement controlled by the RAG foundation, a diversified successor of the former Ruhrkohle AG. The latter was founded in 1968 by government to consolidate the many marginal collieries and gradually phase out coal mining. As RAG has received direct and indirect governmental subsidies for decades (including a compulsory levy on coal-based energy termed 'Kohlepfenning, coal penny later found to be unconstitutional) some of the now used capital originally also came from taxes (RAG 2019). Unlike South African gold mines, the Ruhr area is not plagued by excessive AMD-formation allowing to omit costly neutralisation for the bulk of the pumped water. To what extent this may change in future when all mines are flooded to the higher levels at around 600 m below surface (for saving pumping costs) remains to be seen.

(iii) German lignite mines: In contrast to hard coal mines in the Ruhr area acidification does occur in former lignite mines in south-east Germany, where large lakes formed in flooded open pits with pH-values below 3 necessitating regular liming among other measures. High sulphate and iron levels reaching the river Spree also pose a challenge for downstream water purification as far away as Berlin. Similar to South Africa, where good quality water from the Vaal Dam is used to keep TDS levels in the AMD-impacted downstream part of the Vaal River below 600 mg/l efforts are made here, too, to keep sulphate levels below 450 mg/l by releasing water from upstream dams in Bautzen and Quitzdorf. This, however, proved to be difficult to maintain during an extended dry-weather-period in 2018 when the dilution capacity of the two dams was exhausted triggering, inter alia, an increase of the maximal permissible sulphate concentration to 500 mg/l sulphate (LfU 2018).

With hundreds of thousands of closed and often abandoned mines worldwide associated challenges truly are of global dimension. As resource-restricted economies in developing countries of the global south are among the most affected, simply copying cost-intensive pump- and-treat approaches employed in affluent countries is not sustainable. This paper thus aims to identify innovative alternatives for avoiding perpetual costs being burdened onto future generations through turning mine legacy sites from liabilities into assets.

To this end, a review of existing technologies was conducted focussing on integrated solutions within the water-energy nexus as an area of growing importance, especially in the field of generating and storing renewable energy. Main criterion for selecting promising technologies was their potential to sustainably reduce long-term costs for post-closure mine water management. The aim is not to exhaustively discuss technical detail but rather to stimulate discussion of alternatives to conventional approaches of remediation. Technologies covered in this paper relate to the following aspects of post-closure mine water management:

- Extracting chemical energy from mine water: PRO, RED.

- Harvesting geothermal energy: wind, water.

- Storing (renewable) energy: PHES, UPHES, CAS, Redox flow batteries.

- Generating renewable energy: PV, SUT and biofuel.

GENERATING RENEWABLE ENERGY: EXTRACTING CHEMICAL ENERGY FROM MINE WATER

Core concept

Mine water frequently contains significantly higher salt concentrations than freshwater. Through utilising the natural tendency of concentration differences between water bodies being equalised the chemical potential of mine water can be utilised.

One option is to use the osmose-driven pressure differences between interacting freshwater and mine water columns for generating mechanical energy that can be converted into electricity using Pressure Retarded Osmosis (PRO) technology.

Alternatively, the osmotic movement of dissolved cat- and anions from mine water can also be used to directly generate electricity through separating differently charged ions for creating electrical potential differences that drive a direct current (DC), a technology known as Reverse Electrodialysis (RED). Both technologies are briefly outlined below.

Pressure retarded osmosis (PRO)

The salinity gradient between polluted mine water and freshwater (ground- or surface water) drives a natural process of dilution known as osmosis whereby water molecules from the dilute water phase diffusely migrate via a semipermeable membrane into the higher mineralised mine water until differences in salt concentration are equalised. The movement of freshwater molecules does not require any additional fuel but is purely driven by the salinity gradient and therefore also known as «salinity gradient power» or «blue energy» (Siebers 2012).

As freshwater molecules move across the membrane into the mine water column volume and water level are increased in the latter. For seawater, for example, the resulting height difference to the freshwater column is 270 m translating into a hydraulic pressure difference of 26.5 bar that can be converted into electricity via pistons or turbines. Invented in 1973 in Israel, the world's first osmotic power plant based on PRO technology was opened by the power utility Statkraft in 2009 in the small coastal town of Tofte (Norway) employing the salinity gradient between a local river and seawater yielding a capacity of 10 kW. For Norway alone it is estimated that 12 TWh of 'blue energy' could be produced covering some 10 % of the country's total electricity need (FPTM 2019). Depending on salinity and water throughput (0.5-1 m3/s; ca. 4-9 Ml/d) PRO-plants, under realistic conditions, could produce energy outputs at MW-scale (Siebers 2012).

Application in mine remediation would be best suited for sites with highly saline mine water and sufficiently large resources of clean freshwater nearby (at least about ten times the treated mine water volume depending on salinity) to achieve the required dilution and energy output. While this may limit applications in arid areas suffering from water shortages the technology is well suited for mines with abundant ground and surface water. In addition to humid areas this may also include mines in dry environments operating below water-rich formations as is the case with many South African gold mines.

Apart from supplementing pumping costs through continuously produced, clean free-of-charge energy, no waste product (such as sludge or brine) is to be disposed of like in conventional pump-and-treat approaches such as neutralisation or reverse osmosis (RO). In fact, through diluting mine water with freshwater a good quality water- mix is produced that may either be sold or discharged into nearby water courses without having to consider flow conditions in receiving streams. In view of recent discharge restrictions in Germany due to low dilution capacity of rivers following prolonged dry weather spells in 2018, this may be of increasing future importance for maintaining operational continuity. If RO-based water treatment plants are located near a mine the generated waste brine may be used to increase salinity of the mine water thereby raising the energy output.

Potential applications in Germany may include hard coal mines where overlying Permian evaporites result in highly saline mine water potentially exceeding the dilution capacity of relatively small streams used for disposal. Also, salt mines struggling to dispose of their highly saturated brines are well suited. For all saline mine waters, however, low concentrations of scale-generating constituents such as Ca and Mg (forming calcite) and Fe and Mn (forming iron/ manganese hydroxide precipitates) are best as otherwise coatings and scales may damage the membranes.

Applications in semi-arid South Africa are limited by the general scarcity of fresh water at many mines. However, this is different for mines in and around the greater Johannesburg metropolitan areas where large amounts of treated sewage effluents exceeding local mine water volumes by over 10 times could be used.

Current technological challenges mainly relate to the size of the required membrane area approaching millions of square metres. In order to minimise associated space requirements rolled-up membranes are currently investigated. Capital expenditure relates mainly to turbines and pressurised containers as well as membranes. Running cost relate to maintenance, personnel and the regular replacement of membranes.

Reverse electrodialysis (RED)

This type of energy generation is based on the separation of charged ions naturally contained in mine water using successive layers of semipermeable anisotropic membranes through which the mine water migrates. Accumulating the charge differences between salty mine water on the one side of the membrane and clean fresh water on the other drives a direct current. In 1977, the technology was patented in the USA by S. Loeb from Israel.

Since the end of 2014, a 50-kW-pilot test plant operates on the Afsluitdijk in The Netherlands utilising the difference in electrical potential between freshwater in the Ijsselmeer and seawater of the Wadden See (part of the North Sea) following a successful 8-year test period. The objective is to demonstrate technical feasibility in real-life conditions. At an increased through-flow of 1 m3/s the plant could produce approximately 1 MW of electricity despite a rather modest salinity gradient. For the future, an extension to 200 MW capacity is envisaged. At an average of 3300 m3 of river water running into the sea per second in the whole of the Netherlands a total of 4.5 GW could be harvested using RED technology (Siebers 2012).

As energy is produced continuously RED could be used to supplement pumping costs. In order to minimise DC-AC conversion losses DC-pumps should be used. RED plants are commonly built modular consisting of stacked cells with a capacity of 250 kW each with each cell the size of a shipping container. The successful testing from 2006 to 2014 and the operation phase thereafter together with the envisaged extension of the pilot plant indicate that the technology is feasible under the testing conditions.

Like with the PRO technology, mines with highly saline water and sufficient freshwater resources are best suited for applying RED.

HARVESTING GEOTHERMAL ENERGY

Core concept

The extraction of geothermal energy is based on the earth's temperature increase from an average of 15°C on surface to over 6000°C at the core creating a so-called geothermal gradient. This gradient varies geographically from around 1°C/100 m in old and stable geological structures (such as cratons within which the South African gold mines are located) to over 20 °C/ 100 m in volcanically active zones. The average gradient in Germany is around 3°C/100 m (https://www.geothermie.de/bibliothek/lexikon-der-geothermie/g/geothermischer-gradient.html; accessed 12 May 2019). Depending on the depth of mine and geological settings pumped mine water may be considerably warmer than water on surface. While heat recovery from water is meanwhile well established the same is not true for heated air exhaled by mines. Driven by air temperature differences many mines exhibit natural air movements through shafts and tunnels in form of lateral and vertical drafts that often are strong enough to drive wind turbines. Technologies extracting energy from wind and water of mines are briefly discussed below.

Geothermal wind energy from mine voids

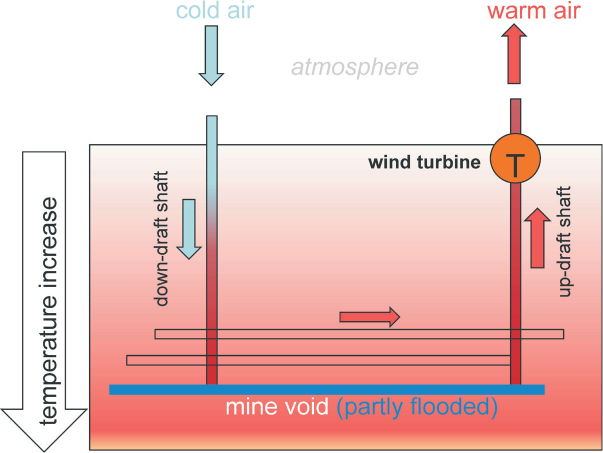

Increasing rock face temperatures in deeper parts of the mines lead to increased temperature of the ambient air and associated convection driving drafts through tunnels and shafts of the underground void. Rising air leaving the void, in turn, sucks in cooler air from surface which will again be heated in deeper parts of the mine creating a continuous circulation. The escaping air can drive (vertical) wind turbines installed in shaft openings creating renewable energy with the output depending on wind speed. The higher the difference in air temperature between surface and mine void, the higher the wind speed and associated energy yield (Fig. 1).

Fig. 1. Schematic sketch of using geothermal drafts form closed mines for wind energy generation

Of course, this concept provides that shafts are not sealed and exhalation of radon is below permissible limits.

The technology was patented in 2009 in the USA (DuBois 2014, 2018) but has not yet been implemented, not even on pilot scale. However, modelling based on conditions of the Blyvooruitzicht gold mine (South Africa) indicated, in principle, the technical feasibility of the concept.

Advantages of the technology include the relatively low initial capital requirement and the continuous generation of cost-free, clean and renewable electricity. Given the simple structure of the system little maintenance and on-site presence is required rendering the technology suitable for autonomous operation in remote locations especially at sites where no grid connection exists. Compared to intermittent energy supply from solar panels and conventional wind turbines this system operates continuously day and night all year round albeit with fluctuating outputs. Owing to diurnal and seasonal air temperature fluctuations on surface energy outputs vary between maxima in cold winter nights and minima at hot summer days. In addition, in partially flooded mines the technology may also be used to extract water through condensing moisture contained in the warm escaping air. This (essentially distilled) water could either be used directly on site (e.g. in remote arid environments) or be provided to local users. The disadvantage of comparatively small energy yields per turbine (kW-scale) could, to some extent, be overcome by installing several turbines at different shafts.

As the technology is based on temperature differences mines with steep geothermal gradients and constantly low surface air temperature (as found e.g. in mountains or higher latitudes) are suited best. The technology may complement mine-water heat recovery systems provided that flooding the mine void did not unduly reduce temperature differences. Owing to the continuous production of energy and water the system is particularly attractive for remote mines (e.g. in mountainous areas) where little technical infrastructure exists.

Geothermal heat from mine water

Due to the low efficiency of converting heat into electricity, warm mine water is preferably used for directly heating buildings or for cooling if used as energy source for heat pumps. To this end heat exchangers are commonly employed to avoid scaling of warm water distribution pipes and allow for subsequent treatment of the mine water where required. Ramos et al. (2015) list 18 abandoned mines worldwide where geothermal heat is recovered from mine water.

This includes a former colliery in Springhill, Nova Scotia (Canada) as one of the first mines worldwide where the concept has been successfully applied since 1987. It utilises 18 °C-warm water from a 1350-m-deep mine as source for heat pumps at a relatively flat geothermal gradient of just 1.5 °C/ 100 m. Being overwhelmingly used for cooling during summer more heat is returned to the mine void than extracted for heating in winter. The system has significantly lower operating costs than a comparable oil-based equivalent and paid back investment in under one year. In designing the system care was taken that water cooled down on surface to 3 °C is not returned directly to the point of underground extraction in order to avoid an incremental drop of water intake temperature (Jessop 1995). Despite the comparably low geothermal potential of the mine the system remained financially viable over the last 30 years suggesting applications even at sites with sub-optimal conditions. A recently developed screening tool for assessing viability of geothermal system in abandoned mines may assist in this regard (Ramos et al. 2015). For Germany several sites have been investigated (Roder 2015, Penczek 2018).

In order to capitalise on the great depths of South African gold mines approaching 4 km at places and associated rock temperatures of ca. 60°C it has been proposed to drill boreholes of another 4 km depth from the bottom of the mine to tap into underlying rock temperatures of ca. 120 °C by circulating injected mine water through rock fractures (Ntholi 2018).

Advantages of geothermal heat recovery from mine water include the permanent availability of heat energy for heating as well as cooling utilising the large specific thermal capacity of water. Disadvantages include the formation of calcite and iron-hydroxide scales in pipe systems triggered by temperature changes which frequently are also radioactive due to the presence of natural radioisotopes such as uranium, radium and thorium in mine waters. Technologies to effectively prevent radioactive scaling in geothermal systems are developed by Friedrich et al. (2016).

STORING (RENEWABLE) ENERGY

Core concept

Apart from using exhausted mines for generating energy this section explores they could also be used to store energy, especially renewable energy from intermittent sources such as sun and wind. In this regard mines provide two major assets: large cavities in which energy-storage media such as water, compressed air or chemicals can be stored, and depth that allows to transform potential energy into kinetic energy and visa versa and creates high water pressure. The below discussed technologies exemplify how these properties of mines may be used, either individually or in combination, to store surplus electrical energy and release it back into the grid when needed.

Pumped hydro energy storage

Pumping water against gravity from a lower to a higher reservoir using surplus electricity and releasing it again via turbines in times of need is the base of the over 100 years- old pumped hydro energy storage (PHES) technology. Employed in thousands of hydro power plants worldwide PHES is currently the only technology able to store electrical energy at MW-scale. Based on deriving revenue by using off- peak electricity for pumping (e.g. at night) and selling more expensive electricity generated during peak demand (e.g. during daytime) PHES can operate economically as long as associated energy conversion losses of about 20 % can be recovered by the day-night price spread.

Using off-peak electricity to compress air and let it expand again later the same principle can be used in socalled compressed air storage (CAS) systems. PHES and CAS may be used in surface and underground mines providing much needed storage capacity for intermittently produced renewable solar and wind energy.

In addition, a similar concept based on water pressure may be used to store energy even in underground mines already flooded.

PHES in open pit mines

The worldwide first example of an abandoned mine being successfully converted into a renewable energy hub is the Kidston Goldmine in Queensland (Australia), where two adjacent open pits with different base levels were connected by an underground tunnel housing a pump and two turbines in order to serve as a PHES in which solar energy from an adjacent PV park is stored during night time. The mine now continuously produces 50 MW of solar energy fed into the grid at rates carefully designed to not exceed demand as temporary oversupply could cause prices drop. Following a major weather-related black out of the power grid the project enjoyed political support that helped funding the project in the region a few years earlier. The remoteness of the site is offset by exceptional high yields of solar energy n this part of Australia and the fact that by using existing open pits constructions costs for the PHES were reduced by 60% compared to conventional plants. While similar conditions may be found elsewhere it was the politically motivated financial support by Australia's Clean Energy Finance Corporation that secured the project (Bloomberg 2019, Kidston 2018).

The application of the concept to large lignite open pits was also proposed where low topographic elevation differences are offset by extremely large water volumes. Using only a tenth of the 4.5 bn m3 of water stored in the 68 open-pit lakes in the Lausatia region and around Halle/ Leipzig some 78 GW could be stored assuming a hydraulic head of just 80 m (Schulz 2009). A recent study confirmed the technical feasibility of converting lignite pits into PHES for the Hambach-Garzweiler-Inden region in western Germany, too (Thema and Thema 2019).

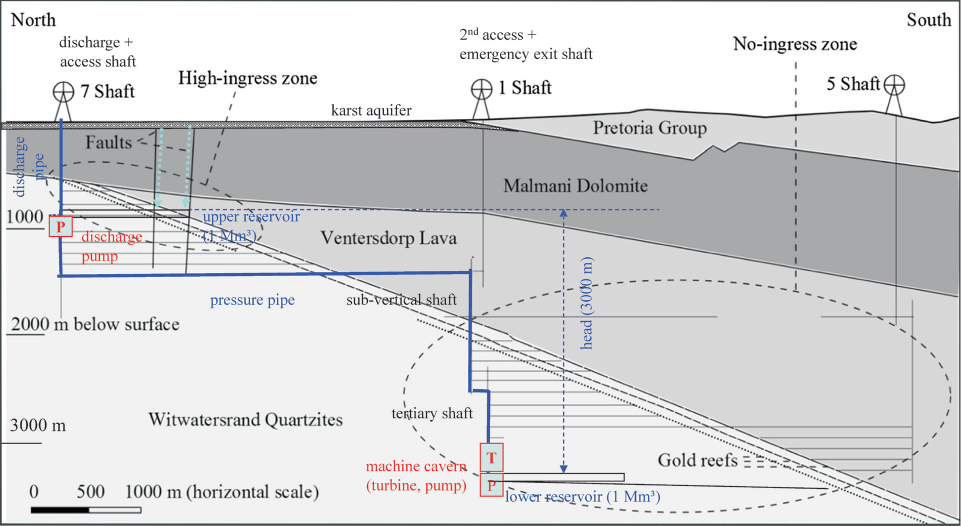

Underground mines

As conventional PHES require topographic elevation differences mostly found in (scenic) mountainous areas suitable sites for new plants are rare and often trigger public resistance despite the generally accepted need for storing renewable energy. By converting mines into underground pumped hydro energy storage (UPHES) plants this problem is averted. The deeper the mine and the larger the circulated water volume, the higher the energy storage capacity easily approaching hundreds to thousands of MW. Various designs have been proposed ranging from closed loop systems circulating a fixed volume of water to open ones integrating continuously generated ingress water. While all UPHES locate the lower reservoir underground either utilising existing tunnels or proposing new excavations, some place the upper reservoir on surface while others use existing underground tunnels at lower depth for that purpose. As underground excavation costs account for the majority of capital expenditure such design differences have significant cost implications. While feasibility studies in German hard coal mines propose to freshly excavate a ring-type of lower reservoir underground resulting in significant costs, studies on South African gold mines propose to utilise the vast underground mine void stretching from surface to several thousands of meters underground (Niemann et al. 2015; Niemann 2018; Zeller 2018; Winde et al. 2017). For specific conditions of deep level gold mines operating below water-rich karst aquifers in South Africa Winde et al. (2016) proposed an open system which integrates the overlying karst aquifer as feed water reservoir providing between 70 to 100 Ml/d of clean ingress water. In addition to exceptional high energy yields of several hundred MW resulting from the large hydraulic head in ultra-deep mines, the interception of ingressing water before flowing through the mine void also prevents water pollution and the need to treat it. Using the concrete example of Driefontein Winde (2018) calculated a total revenue from selling peak electricity and clean water of over R 1.1 bn per annum, with the sale of clean water accounting for some 20% (Fig. 2).

Fig. 2. Proposed UPHES at a deep level gold mine in the dolomitic karst area of the Far West Rand

The major advantage of deep-level South African gold mines over German mines in the Ruhr area or the Harz mountains is, however, not so much the greater depth but rather the pronounced peak vs. off-peak price differences varying from 150 % (summer) to 600 % (winter). Owing to the increased input of solar energy during daytime following a change of energy policy in Germany, the formerly utilised day-night differences are now much reduced or have disappeared altogether. At the same time erratic peaks of solar and wind energy that exceed demand increasingly cause significant costs by grid owners having to sell surplus energy at 'negative prices', i.e. paying neighbouring countries for accepting the expensively generated energy. In 2018, the resulting loss was estimated at approximately € 1bn, i.e. over 4 times the total pumping costs in the Ruhr area further pushing the local price for electricity in Germany which already is the highest in Europe (Bellinger 2018). Since UPHES would be able to easily accept such electricity peaks this may constitute a viable business model. In view of globally rising shares of poorly predictable solar and wind energy market mechanism may soon be developed to pay PHES and UPHES not only for energy generated but also for providing services ensuring grid stability such as energy storage, buffering erratic peaks, providing regulating power, frequency stabilisation as well as black start capacity to name but a few.

Suspended weight gravity energy storage (SWGES)

This technology is based on the same principle as pumped hydro storage except for the fact that it uses a solid weight (e.g. a block of concrete) which is lifted against gravity instead of water. The solid weight is suspended on a rope inside a vertical shaft. During off peak time or excess generation of energy an electrical motor winds up the weight to the surface where it remains suspended until energy is required again. Releasing the weight down into the shaft again turns the motor into the opposite direction. Now acting as a dynamo, the motor feeds electrical energy back into the grid at peak tariffs that are significantly higher than the ones paid for pulling the weight up. According to Menendez et al. (2020) a weight of 3 kt lifted by 600 m could generate 3.81 MWh per cycle with typical cycle times varying between 0.25 to 2 hours. This compares to nearly twenty times the energy output (718 MWh) of a UPHES for 4-16 hours per cycle (i.e. up to 8 x times longer) which utilises the same depth and 0.5 Mm3 of water (i.e. 500 kt). Like UPHES, SWGES would require non-flooded underground mines and open shafts still being intact. While in terms of storage capacity and duration for which peak energy could be provided SWGES is limited compared to competing technologies like UPHES it may be an option in settings were water is not available and peak load periods are short.

Water pressure-based energy storage

In order to also utilise underground mine voids already flooded which for other uses would have to be emptied again at significant costs komma a new technology is proposed jointly developed by the construction company Hochtief and the Fraunhofer Institute for Energy Economy and Technology (IEE) in Kassel (Germany). In this technology interconnected hollow concrete spheres are lowered into the water and allowed to fill with water via a remotely controlled valve. Pumping out this water with surplus wind energy creates a vacuum inside the concrete balls. During peak time the valve is opened again, and the water allowed to flow back into the balls driving a turbine (which also acts as pump) that generates electricity transmitted via cable to surface (https://www.ingenieur.de/technik/fachbereiche/energie/betonkugeln-im-bodensee-windstrom-speichern/, accessed 15 May 2019). In November 2016, a pilot-facility was successfully tested at the Bodensee (Germany). A similar technology substituting the rigid concrete balls by flexible balloons is currently investigated at the MIT in Cambridge, USA. Using the pressure of water surrounding submerged objects water depth impacts on the efficiency of the system. While not specifically designed for mining remediation we believe the technology may hold some promise to be applied in this context especially at flooded mines for which little alternative use exists.

Compressed air-based energy storage (non-flooded underground mines)

CAES is similar to the water-pressure based technology except that it stores electrical energy not in a vacuum but in compressed air. Using underground mine voids for storing pressured air requires airtight structures most commonly found in salt mines (Kaiser et al. 2017). Where flooding of salt mines is not a feasible option (e.g. for protecting groundwater resources from salination) this concept could be considered. For Germany, which produces much of its wind energy at the northern shores salt mines in the nearby lowland of north Germany would constitute an alternative to pumped hydro storage which is mostly confined to faraway mountains in the south that are poorly grid-connected to producers in the north.

Existing pilot projects in Germany (Huntdorf) and the USA (McIntosh) are successfully operated for years but are still well below the 100 MW-scale. As compressing air produces heat different systems exist to manage and reduce the increase in temperature (adiabatic vs. isothermal CAES respectively) and the associated energy loss. For offshore applications the use of flexible balloons to store compressed air was also considered which could also be applied to flooded mines. Despite tests on various mines in Japan (hard rock and coal mines) no application in former mines exists to date (Kaiser et al. 2018).

Electrolytic energy storage (EES)

In contrast to the above discussed technologies EES does not primarily use the depth of mine but its underground void space. Energy is stored based on the rechargeable (redox-flow) battery principle. During off-peak times cheap electricity drives electrons from a catholyte solution (positively charged) to an anolyte solution (negatively charged) via an ion-selective membrane separating both solutions. Once charged komma the electrolytes are pumped into two separate underground storage caverns of say 100,000 m3 each, where they can be kept for several months. The stored energy is released again by pumping both solutions back to the membrane where electrons spontaneously migrate in reverse direction generating electricity in the process. A disadvantage of the system is the high toxicity of electrolytes which includes toxic heavy metals (e.g. vanadium) and sulphuric acid, for example. However, recently seawater and recyclable polymers have been identified as suitable non-toxic substitutes (Janoschka et al. 2015). A pilot plant in Jemgum (Germany) using underground salt deposits, since 2017, generates 120 MW. However, to date the concept was not yet applied to closed mines. Watertight, non-flooded underground voids would be potential candidates for future applications.

GENERATING RENEWABLE ENERGY

Core concept

In addition to storing renewable energy generated elsewhere remediated mines may also generate their own renewable energy utilising the abundantly available brownfield areas with long-term use restrictions. Opportunities range from installation of solar panels, wind turbines and solar updraft towers as well as using tailings deposits for growing biofuel.

Photovoltaic (solar panels)

While installation of photovoltaic solar panels on remediated mine dumps and other former brownfield sites is already frequently practiced in Germany (e.g. at former uranium mines in Saxony and East Thuringia Wismut and copper mines in the Mansfeld region of Saxony Anhalt) it is increasingly also applied to un-remediated sites in order to save costs for decontamination. Arguing that former dumps and land fill sites will not be turned into revenue-generating assets even after costly remediation specialised US- companies now actively seek out cheap contaminated areas where renewable energy is popular but free land scarce. Sites include coal-ash ponds in SW Virginia (USA), mines in eastern Kentucky, landfills in New England and even parts of the nuclear zone at Chernobyl (Ukraine). BHP Group, as the world's largest mining company, plans to install solar panels and energy storage facilities at mine legacy sites in Arizona and New Mexico (USA). The Drayton coal mine in Australia is also planned to be converted into a 25-MW-solar farm (Bloomberg 2019). In China 87 ha of open water surfaces of a flooded coal mine were covered with floating solar panels generating 40 MW (Zhu 2018).

Plans to install solar panels on large flat-topped gold tailings deposits in South Africa comprising hundreds of square kilometres were abandoned despite relatively high solar yields (double as high as in Germany) because of windblown tailings dust potentially scratching and dimming panel surfaces.

Wind turbines, SUT and biofuel

Wind turbines.

Since wind speed exponentially increases with height above ground the placement of turbines on up to 80-m-high tailings deposits in SA goldfields would increase energy output at no additional cost. Given the generally flat topography of the South African interior plateau (Highveld) protruding structures such a tailings dams would elevate wind turbines well above surrounding land and increase energy yields. Generated energy could directly be stored on site using pumped hydro storage provided, of course, that the geotechnical stability of the high-rise turbine structure could be assured in the grainy substrate.

Solar updraft towers (SUT):

Alternatively, large flat tailings areas could also be covered by transparent material (e.g. polyester foil, glass etc.) channelling the heated air below towards a tall chimney in the centre were convection drives a wind turbine that generates electricity. A pilot model of such SUT operated successfully for 7 years in Manzanares (south of Madrid, Spain) with 46 ha of land feeding a 195-m-high chimney of 10 m in diameter generating 50 kW. In 2010, a SUT was built in Jinshawan (Inner Mongolia, China) for USD 208 million producing 200 kW using a 50-m-high tower and a glass- covered feeding area of 277 ha (https://en.wikipedia.org/wiki/Solar_updraft_tower). A major reason for locating the plant there was to improve local air quality through covering large areas of loose sand with glass in order to reduce windblown dust pollution. As large and unvegetated tailings deposits in South Africa are also a major dust source affecting densely populated mining areas SUT would be a possible technology for reducing air pollution and save precious and scarce water resources currently used for dust suppression by simply wetting the tailings surface. With footprint areas of several hundreds to thousands of hectares tailings dams would be sufficiently large to delivery meaningful energy yields given the high insolation typically found in the South African goldfields. By shielding tailings from infiltrating rainwater SUT would also dry up outflow of contaminated tailings seepage as one of the most problematic sources of water pollution in the Witwatersrand basin. Given the tight financial situation of the few remaining gold mines, however, the relatively large capital expenditure required for SUT is likely to present an obstacle for rapid implementation.

Biofuel

Turning vast areas of toxic mine waste into productive use by growing biofuel on top of tailings dams could transform tailings from environmental liabilities requiring costly maintenance into economic assets that provide local communities with opportunities for sustainable postclosure development. By utilising several hundreds of square kilometres of barren tailings surface, biofuel would no longer compete for land with food production that recently caused global increases in food prices.

Successful test trials of improving soil properties of tailings material to create lasting vegetation covers suggest that certain biofuel plants can indeed be grown in augmented tailings substrate. Through developing nontoxic top soil layers also dust pollution could be reduced at no additional costs. Preferably, plants not requiring extensive irrigation should be employed in order to not inadvertently accelerate seepage-related water pollution.

CONCLUSIONS

Currently driving about 45 % of the global economy mining is, and probably will remain, a crucially important activity that not only creates jobs and revenue but also provides mineral resources needed for sustaining a growing and increasingly resource-hungry human population (Cloete 2019). Given such degree of economic importance, now and in future, it is imperative to make mining ecologically sustainable. While associated impacts on men and environment are generally deemed acceptable as long as benefits are derived, this changes once mines close. No longer providing employment or revenue many closed mines turn into costly legacy sites with associated costs burdened onto taxpayers and future generations. This paper explores a range of innovative technologies aimed at reducing associated costs by turning closed mines from environmental liabilities into economic assets focussing on the extraction, generation and storage of renewable energy. Table 1 provides an overview on technologies discussed.

Table 1. Potential technologies for extracting, generating and storing renewable energy at closed mines

Energy type | Technology | Used media | Suitable mines | Existing applications |

|---|---|---|---|---|

Hydro-chemical | PRO | saline mine water | flooded underground voids, salt mines | 1 x non-mining pilot project (Norway) |

E-generation | RED | saline mine water | flooded underground voids, salt mines | 1 x non-mining pilot project (Netherland) |

Geothermal heat extraction | heat pump (vertical) wind turbines | warm mine water convective mine air/ upward drafts | flooded underground voids non-flooded/ partially flooded voids | 18 x mines (worldwide) none |

RE-generation solar wind biofuel RE-storage | PV SUT conventional wind turbines PHES UPHES SWGES CAES Vacuum EES | solar radiation solar radiation atmospheric wind solar radiation, biomass surface water ingress water solid weights compressed air mine water electrolytic solutions | on surface, brownfields tailings dams tailings dams tailings dams on surface, open pits non-flooded underground voids underground salt mine caverns flooded underground voids non-flooded underground voids | several (USA, Germany, Australia, China) 2 x non-mining pilot projects (Spain, China) none none, various test sites 1 x gold mine (Queensland, Australia) studies in Germany, Finland, South Africa and other countries unknown 2 x non-mining pilot plants (Germany, USA) 1 x non-mining pilot test (Bodensee, Germany) 1 x pilot plant (Jemgum, Germany) |

In some instances, the above technologies can be synergistically combined e.g. by storing renewable energy generated on site in underground mine voids. Combining pumped hydro storage with heat pumps that cool in summer and heat in winter is currently investigated in Switzerland (Gigler 2018). The recovery of geothermal heat from mine water may be complemented by using upward air drafts of mine from the underground void to continuously generate wind energy while covering tailings with solar updraft towers would simultaneously create energy and minimise water and air pollution. In some instances, it may be better to combine several technologies at smaller scale instead of aiming for a single large capital-intense project that struggles to attract investors. Such incremental steps towards alleviating the financial burden are not confined to energy-related technologies discussed here, but could also include complementary activities like:

- commercially viable extraction of resources from mine water including commodities of economic criticality like rare earth elements, precious metals or salts used in fertilizer (Friedrich 2018; Hoth et al. 2015, Elwert 2018; Zhu 2018)

- using energy from mines for energy-intense technologies such as data mining, crypto currency generation and tamperprove certification of critical commodities such as gold, phosphorous, cobalt and diamonds creating a competitive advantage in the promising field of digital technologies (Friedrich et al. 2018)

- food production through horticulture (heating greenhouses with mine water) or aquaculture (suitable water quality provided)

- utilising deep-level mines for scientific research like underground detectors for neutrino beams from CERN as proposed for a Finnish mine or for atmospheric cloud formation processes as suggested for ultra-deep gold mines in South Africa in the 1980s.

- use of ultra-deep mines as safe repository for hazardous material

- establishing revenue-generating land uses such as tourism as successfully implemented in 61 so-called 'mine parks' in China that feature entertainment facilities (Zhu 2018) or water-linked recreation in artificial lakes of flooded open pits in former lignite mining areas of SE-Germany

- reopening closed mines for extracting unmined commodities following increases in market prices (Goedecke 2015) etc.

In order to make post-closure solutions sustainable close and trust-based consultation with local communities is essential. Where public acceptance of designed afteruses is low or of little benefit to surrounding communities, solutions are unlikely to last. That means socio-economic conditions of host communities must be considered when designing post-closure concepts. E.g., while high- tech solutions, entertainment and recreation may work well in affluent societies, job-intense agriculture and food production may be more appropriate in resource-restricted settings of developing countries.

Also, solutions for mines in areas with well-developed infrastructure, many potential energy users and a qualified workforce nearby will differ from mines in remote areas with no water or electricity, quite independent from the general economic status of the host country.

In almost all cases, however, political support is required as closing mines generally suffer from shortage of funds and an unwillingness to invest despite the introduction of compulsory remediation funds some years ago.

Furthermore, in deciding on larger capital-intense projects such as UPHES a macro-economic view often is more appropriate than applying a micro-economic business case approach. E.g., while a UPHES may not be able to generate operational profit on its own it may still be economically viable on national level through saving public funds otherwise spent on perpetually treating polluted water flowing from that mine. Other aspects of national relevance not captured in microeconomic views include strategic water security, stability of the national energy grid, long-term transition of the energy system etc.

Another major obstacle in implementing innovative solutions, especially in government-controlled remediation projects, is the lack of incentives for officials to take risks. While potential failures may be career-threatening there are no mechanisms to reward bold decisions that help saving public funds. In many instances such savings are not even captured by expenditure-focussed accounting systems, leave alone being credited to the responsible official. This often also applies to larger mining companies which tend to be risk and innovation aversive. Creating climates that encourage innovative solutions may thus well be the single most important step towards achieving truly sustainable long-term solutions.·

References

1. Acatech [ed.] (2017). Rohstoffe für die Energiewende. Wege zu einer sicheren and nachhaltigen Versorgung. Stellungnahme, Berlin (in German).

2. Ahmed N. (2018). We don’t mine enough rare earth metals to replace fossil fuels with renewable energy. [online] Available at: www.vice.com/en_us/article/a3mavb/we-dont-mine-enough-rare-earth-metals-to-replace-fossil-fuels-with-renewable-energy [Accessed 12 December 2018].

3. Bellinger I. (2018). National Geographic Germany: Neue Energien, December 2018, 127-132.

4. Bloomberg (2019). ‘Land no one else wants’ gets solar as coal-and-nukes era fades [online]. Available at: www.miningweekly.com/article/land-no-one-else-wants-gets-solar-as-coal-and-nukes-era-fades-2019-04-25 [Accessed 25 April 2019].

5. Cloete K. (2019). Plea for collaboration. Mining Weekly, 22-28 February, 16, quoting M Cutifani, CEO of Anglo American at the Mining Indaba in Cape Town, South Africa.

6. Dombrowski B. (2018). Remediating mining legacy site: Case study hard coal mining in the Ruhr area. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 22-23.

7. DuBois JR. (2014). United States Patent No. US 8.677.752 B2, power generation system.

8. DuBois JR. (2018). Generating Renewable Energy and Recovering Water from Underground Mines. Hand-out brochure, unpublished, 5.

9. Eberfalvi J., Nemeth G., Varhegyi A. (2015). Challenges of the after-care activities on the uranium mining and ore processing legacy sites in Hungary. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 361-370.

10. Elwert T. (2018). Recovery and reprocessing of mine tailings: experiences from Germany. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 38-39.

11. FPTM (Future Power Technology Magazine). (2019). Statkraft Osmotic Power Plant, the First Osmotic Power Or Salinity Gradient Power Generation Plant. [online] Available at: www.power-technology.com/projects/statkraft-osmotic/ [Accessed 26 August 2019].

12. Friedrich et al. (2016). Elektrochemische Abtrennung tailingsrelevanter Schwermetallkationen und geogener Radionuklide aus geothermalen Tiefenwässern. In: Proceedings Geothermie Kongress, Essen 2016. [online] Available at: www.geothermie.de/bibliothek/konferenzdatenbank [Accessed 20 May 2020].

13. Friedrich H-J. (2018). Resource extraction from mine water. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 40-41.

14. Friedrich H-J., Viehweger K., Winde F. (2018). Innovative Optionen zur Energiegewinnung aus Grubenwasser und gefluteten Grubengebäuden. Projektantrag zum Themenbereich: Inwertsetzung energetischer Nutzungspotenziale von Grubenwasser. Forum Bergbau und Wasser, Deutsches Stiftungszentrum GmbH. Dez. 2018, unveröffentlicht, 31 Seiten. (in German).

15. Ghenai C., Janajreh I. (2013). Comparison of resource intensities and operational parameters of renewable, fossil fuel, and nuclear power systems. Int J of Thermal & Environmental Engineering, 5(2). [online] Available at: www.researchgate.net/publication/275965432_Comparison_of_Resource_Intensities_and_Operational_Parameters_of_Renewable_Fossil_Fuel_and_Nuclear_Power_Systems, 95-104, DOI: 10.5383/ijtee.05.02.001 [Accessed 20 May 2020].

16. Gigler B. (2018). Die Zukunft der Energieversorgung: Kombinierter Energiespeicher als Schlüsseltechnologie. [online] Available at: www.idw-online.de/de/news704503 [Accessed 23 October 2018].

17. Goedecke M. (2015). Wismut-Erbe und sächsische Rohstoffstrategie – eine noch nicht abgeschlossene Erfolgsgeschichte. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 237-250. (in German).

18. Helioscsp (2010). China’s first solar tower plant starts operating in desert. Solar Thermal Energy News. [online] Available at: www.helioscsp.com/chinas-first-solar-tower-plant-starts-operating-in-desert/, updated 28 Dec. 2010 [Accessed 26 Aug. 2019].

19. Hoth N., Wendler C., Kassahun A., Ussath M., Drebenstedt C. (2015). Rückgewinnung wirtschaftstragischer Elemente aus Bergbauwässern – Randbedingungen und Herausforderungen. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 227-236. (in German).

20. Janoschka T., Martin N., Martin U., Friebe C., Morgenstern S., Hiller H., Hager M.D., Schubert U.S. (2015). An aqueous, polymer-based redox-flow battery using non-corrosive, safe, and low-cost materials. Nature, 527, 78-94, DOI: 10.1038/nature15746.

21. Jessop A. (1995). Geothermal energy from old mines at Springhill, Nova Scotia, Canada. IGA [online]. Available at: www.geothermalenergy.org/pdf/IGAstandard/WGC/1995/1-jessop2.pdf 463-468. [Accessed 20 May 2020].

22. Kaiser F., Winde F., Erasmus E. (2018). Storing energy in disused mines: comparing pumped water and compressed air-based technologies. International Journal of Mining and Mineral Engineering, 9(3), 177-195, DOI: 10.1504/IJMME.2018.096096.

23. Kidston S. (2018). Implementing pumped hydro energy storage at an open pit mines: a pilot project from Australia. In: Academy of Science of South Africa: Linking science, society, business and policy for the sustainable use of abandoned mines in the SADC region. Proceedings of the science business society dialogue conference, 28-30 November 2017, Indaba Hotel, Johannesburg, Gauteng, South Africa, 28-30, DOI: 10.17159/assaf.2018/0025.

24. LfU (Landesamt für Umwelt). (2018). Niedrigwassersituation 2018. Arbeitsgruppe: Bergbaubedingte Stoffeinträge in die Spree und Spree Zuflüsse; Ministerium Ländliche Entwicklung, Umwelt und Landwirtschaft, Land Brandenburg; PowerPoint presentation, 10 slides. [online] Available at: www.braunespreewatch.de/images/studien/20181120_Anlage%2010.pdf [Accessed 20 November 2018] (in German).

25. Niemann A. (2018). UPHES feasibility: Case study from German hard coal mines. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 31-32.

26. Niemann A., Hager S., Lux J-P. (2015). Perspektiven der Bergbaufolgenutzung zur Energiespeicherung – Pumpspeicherwerke unter Tage im Ruhrrevier. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 199-206.

27. Ntholi T. (2018). Geothermal energy as a power source for PUMPS, a geo-engineering system designed for in-situ remediation of acid mine water in abandoned Witwatersrand gold mines. In: Academy of Science of South Africa [ed.]: Proceedings of the Science Business Dialogue Conference «Linking Science, Society, Business and Policy for the Sustainable Use of Abandoned Mines in the SADC Region», 28-30 November 2017, Indaba Hotel, Johannesburg, Gauteng, South Africa, 38, DOI: 10.17159/assaf.2018/0025.

28. Paul M., Meyer J., Jenk U., Kassahun A., Baacke D., Forbrig N., Metschies T. (2015). Kernaspekte des langfristigen Wassermanagements an den sächsisch-thüringischen Wismut-Standorten. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 71-86. (in German).

29. Penczek N. (2018). Harvesting geothermal heat from mine water: a pilot project from Germany. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 33-34.

30. RAG (2019). [online] Available at: www.rag.de/ewigkeitsaufgaben/wasserhaltung/ [Accessed 10 May 2019].

31. Ramos E.P., Breede K., Falcone G. (2015). Geothermal heat recovery from abandoned mines: as systematic review of projects implemented worldwide and a methodology for screening new projects. Environ Earth Sci, DOI: 10.1007/s12665-015-4285-y.

32. Röder U. (2015). Geothermische Nutzung von Flutungswässern des Zwickauer Steinkohlereviers. In: Wismut GmbH [eds.]: Reclaimed mining sites between post-remedial care and reuse. Proceedings of the International Mining Symposium WISSYM 2015, Bad Schlema, 31 August – 3 September 2015, 207-214. (in German).

33. Schulz D. (2009). Speicherpotenziale von Pumpspeicherwerken in Tagebaurestlöchern ehemaliger Braunkohlereviere. Forum Netzintegration, Deutsche Umwelthilfe Berlin, 30 September, 29. (in German).

34. Siebers R. (2012). RED Pilot on the Afsluitdijk, The Netherlands. INES, Singapore. [online] Available at: www.deafsluitdijk.nl/wp-content/uploads/2014/06/2012-10-30-Presentatie-door-Rik-Siebers-over-Blue-Energy.pdf [Accessed 19 October 2012].

35. Thema J., Thema M. (2019). Pumpspeicherkraftwerke in stillgelegten Tagebauen am Beispiel Hambach-Garzweiler-Inden. Wuppertal Paper 194, Januar 2019, Wuppertal Institut. [online] Available at: www.epub.wupperinst.org/frontdoor/deliver/index/docId/7211/file/WP194.pdf, 21 [Accessed 20 May 2020].

36. Winde F. (2018). UPHES pre-feasibility: case study South Africa. In: Academy of Science of South Africa: Linking science, society, business and policy for the sustainable use of abandoned mines in the SADC region. Proceedings of the Science business society dialogue conference, 28-30 November 2017, Indaba Hotel, Johannesburg, Gauteng, South Africa, 27-28, DOI: 10.17159/assaf.2018/0025.

37. Winde F., Kaiser F., Erasmus E. (2017). Exploring the use of deep level gold mines in South Africa for underground pumped hydroelectric energy storage schemes. Renewable and Sustainable Energy Reviews, 78, 668-682, DOI: 10.1016/j.rser.2017.04.116.

38. Winde F., Stoch E.J. (2010). Threats and opportunities for post-closure development in dolomitic gold mining areas of the West Rand and Far West Rand (South Africa) – a hydraulic view. Part I: Mining legacy and future threats. Water SA, 36(1), 69-74.

39. Zeller E. (2018). UPHES feasibility: case study Finland. In: Academy of Science of South Africa: Linking science, society, business and policy for the sustainable use of abandoned mines in the SADC region. Proceedings of the science business society dialogue conference, 28-30 November 2017, Indaba Hotel, Johannesburg, Gauteng, South Africa, 30, DOI: 10.17159/assaf.2018/0025.

40. Zhu Q. (2018). Remediating mining legacy sites: case study China. In: Academy of Science of South Africa [ed.] (2018). Proceedings of the Science Business Society Dialogue conference, Linking science, society, business and policy for the sustainable use of abandoned mines in the SDAC region, 28-30 November 2017, Johannesburg, South Africa, 21.

About the Author

Frank WindeGermany

Department Monitoring and Radiation Protection, Wismut GmbH; Research Unit for Environmental Science and Management, North-West University

Jagdschänkenstrasse 29 D-09117 Chemnitz, Germany

Vanderbijlpark Campus, 1174, Vanderbijlpark 1900, South Africa

Review

For citations:

Winde F. Turning Water Pollution Sources Into Assets: Exploring Innovative Options Of Using Abandoned Mines For Generating And Storing Renewable Energy. GEOGRAPHY, ENVIRONMENT, SUSTAINABILITY. 2020;13(2):6-16. https://doi.org/10.24057/2071-9388-2020-03

JATS XML